Welcome to the Goodman GM9S96 Installation Manual, your comprehensive guide for installing the GM9S96 single-stage, multi-speed ECM gas furnace. This manual ensures safe and efficient installation, highlighting key features like up to 96 AFUE efficiency and compatibility with modern HVAC systems. Follow the detailed instructions to optimize performance and comply with safety standards. Proper installation is crucial for reliability and energy savings. Refer to this manual for step-by-step guidance and troubleshooting tips.

Overview of the Goodman GM9S96 Furnace

The Goodman GM9S96 is a single-stage, multi-speed ECM gas furnace designed for efficient heating with up to 96 AFUE efficiency. It features advanced ECM motor technology for quieter operation and improved energy savings. This furnace is compatible with modern HVAC systems and offers reliable performance. Its compact design and durable construction ensure long-lasting service. The GM9S96 is ideal for homeowners seeking a balance of efficiency, comfort, and affordability. With its robust features and eco-friendly design, it stands out as a top choice for residential heating solutions. Proper installation ensures optimal performance and safety.

Key Features and Benefits of the GM9S96 Model

The Goodman GM9S96 furnace offers exceptional efficiency with up to 96 AFUE, ensuring significant energy savings. Its single-stage, multi-speed ECM motor provides quiet operation and precise airflow control. This model features a durable design with a long-lasting construction and is compatible with modern HVAC systems. The GM9S96 is eco-friendly, meeting DOE standards, and includes advanced safety features for reliable performance. Its compact size allows for flexible installation options. Homeowners benefit from consistent comfort, lower utility bills, and reduced environmental impact. These features make the GM9S96 a reliable and cost-effective choice for heating needs.

Importance of Proper Installation for Optimal Performance

Proper installation is critical for the Goodman GM9S96 furnace to ensure optimal performance, safety, and efficiency. Incorrect installation can lead to reduced efficiency, increased energy bills, and potential safety hazards. Trained personnel should follow the manual’s guidelines to guarantee compliance with safety standards and warranty requirements. Proper venting, combustion air setup, and electrical connections are essential for reliable operation. Improper installation may void the warranty and compromise the furnace’s longevity. Always adhere to the instructions provided in this manual to ensure the system operates efficiently and safely, providing consistent comfort and energy savings for years to come.

Safety Precautions and Guidelines

Safety is paramount during the installation of the Goodman GM9S96 furnace. Always follow the manual’s guidelines to prevent injuries and ensure compliance with regulations. Handle components with care to avoid damage and potential hazards. Adhere to environmental and safety standards to guarantee proper operation. Only trained personnel should perform installations, repairs, or adjustments. Failure to comply may result in unsafe conditions or system malfunctions. Refer to the manual for specific precautions and safety measures to ensure a secure and efficient installation process.

General Safety Warnings for Installers

Only trained and authorized personnel should install, adjust, or repair the Goodman GM9S96 furnace. Improper installation can lead to safety hazards, including fire or explosion risks. Always follow the safety precautions outlined in this manual to ensure compliance with environmental and safety regulations. Handle all components with care to prevent damage and potential hazards. Proper storage and handling of equipment are critical to maintaining safety standards. Failure to adhere to these guidelines may result in unsafe operating conditions or system malfunctions. Always prioritize safety to protect both the installer and the end-user. Refer to the manual for detailed safety warnings and procedures.

Handling and Storage Precautions

Proper handling and storage of the Goodman GM9S96 furnace are essential to prevent damage and ensure safe installation. Avoid exposing the unit to extreme temperatures, moisture, or direct sunlight during storage. Store components in their original packaging to protect against dust and physical damage. Handle the furnace and its parts with care to prevent dents, scratches, or bends. Use appropriate lifting equipment to avoid physical strain or component damage. Keep the unit in a dry, clean environment, away from chemicals or flammable materials. Inspect all parts for damage before installation and ensure they are securely fastened during transport. Always follow the manufacturer’s guidelines for storage and handling to maintain warranty validity and system performance.

Environmental and Safety Regulations Compliance

Compliance with environmental and safety regulations is crucial when installing the Goodman GM9S96 furnace. Ensure all materials, such as packaging and waste, are disposed of in accordance with local environmental laws. Use approved refrigerants and handle them properly to prevent ozone depletion. Familiarize yourself with OSHA guidelines and regional building codes to avoid violations. Properly manage venting to minimize emissions and reduce environmental impact. Adhere to safety standards for electrical and gas connections to prevent hazards. Always follow the manufacturer’s recommendations to ensure compliance with all applicable regulations and protect the environment.

System Components and Requirements

The Goodman GM9S96 furnace requires specific components, including a heat exchanger, burners, blower motor, control board, and gas valve. Ensure compatibility with venting pipes, fittings, and required materials. Verify electrical and gas supply specifications to meet installation standards for safe and efficient operation.

Understanding the Furnace Components

The Goodman GM9S96 furnace consists of key components essential for its operation. The heat exchanger transfers heat from combustion gases to the air. The burners produce flames for heating, while the blower motor circulates air through the duct system. The control board manages furnace operations, including ignition and safety features. The gas valve regulates fuel flow to the burners. Additional components like the draft inducer ensure proper venting, and the igniter lights the burners safely. Understanding these parts is crucial for installation, maintenance, and troubleshooting, ensuring the furnace operates efficiently and safely.

Compatibility with Other HVAC Systems

The Goodman GM9S96 furnace is designed to integrate seamlessly with most HVAC systems, offering flexibility for various home configurations. It is compatible with central air conditioning systems, heat pumps, and humidifiers, ensuring a comprehensive climate control solution. The furnace works with standard 24V thermostats and can be paired with smart home systems for advanced control. Its design allows for effortless integration with existing ductwork and ventilation systems. Proper configuration with compatible components ensures optimal performance and energy efficiency. This compatibility makes the GM9S96 a versatile choice for upgrading or installing new HVAC systems in residential settings.

Tools and Materials Needed for Installation

Installing the Goodman GM9S96 furnace requires specific tools and materials to ensure a safe and efficient setup. Essential tools include a voltage tester, gas pipe cutter, wrench set, screwdrivers, pliers, and a vacuum pump for evacuating the system. Materials needed include gas tubing, venting components (PVC pipes and elbows), electrical wiring, and insulation. A drain line kit is necessary for condensate drainage, and a manometer may be required for gas pressure testing. Proper tools and materials ensure compliance with safety standards and optimal furnace performance. Always refer to the manual for specific requirements to avoid installation errors.

Installation Requirements and Preparation

Proper preparation is crucial for a successful installation. Ensure the site meets all local codes and regulations. Plan the layout, gather necessary tools, and prepare the area for safe and efficient installation.

Site Selection and Clearance Guidelines

Proper site selection ensures safe and efficient furnace operation. Choose a location with adequate space, accessibility for maintenance, and protection from environmental elements. Ensure the area is level and clear of flammable materials. Maintain required clearances from walls, windows, and doors as specified in local codes. Verify that the site complies with all safety standards and manufacturer recommendations. Proper drainage and ventilation paths must be planned. Ensure the furnace is installed in an area with adequate airflow to prevent moisture buildup and combustion issues. Follow all local building codes and manufacturer guidelines for optimal performance and safety.

Electrical and Gas Supply Requirements

The Goodman GM9S96 furnace requires a dedicated 120-volt electrical circuit to ensure reliable operation. The circuit must be sized according to the unit’s power requirements, as specified in the manual. A properly grounded outlet should be installed near the furnace. For gas supply, ensure a shut-off valve is installed within 6 feet of the furnace. The gas line must be sized to deliver the required BTU input, and all connections must comply with local codes. Verify that the gas pressure matches the furnace’s specifications. Proper electrical and gas connections are critical for safe and efficient operation.

Drainage and Venting System Preparation

Proper drainage and venting are essential for the Goodman GM9S96 furnace to function safely and efficiently. The condensate drain must be connected to a suitable location, such as a floor drain, ensuring no blockages. For venting, use approved materials like PVC or CPVC, with a minimum vent pipe slope of 1/4 inch per foot to prevent condensate backflow. Ensure all joints are securely sealed to avoid gas leaks. The vent system should terminate outside, away from windows and doors, following local building codes. Proper installation of these systems is critical for preventing hazards and ensuring optimal performance.

Venting and Combustion Air Setup

Proper venting and combustion air setup are crucial for efficient and safe furnace operation. Ensure correct venting systems and adequate combustion air intake for optimal performance.

Venting System Requirements and Options

The Goodman GM9S96 requires a venting system that meets specific criteria for safe and efficient operation. Installers must ensure the venting system is compatible with the furnace’s design, using materials like stainless steel or PVC that adhere to local codes. Direct vent, natural draft, or induced draft systems may be used, depending on installation conditions. Proper vent termination, clearance, and slope are essential to prevent backdrafts and ensure proper airflow. Always follow manufacturer guidelines and local regulations for venting configurations to maintain safety and efficiency, avoiding potential installation issues or performance problems.

Combustion Air Setup and Safety Considerations

Proper combustion air setup is critical for the Goodman GM9S96 furnace to ensure safe and efficient operation. Installers must provide adequate combustion air intake, adhering to local building codes and manufacturer specifications. The combustion air system should be designed to prevent contamination from other vents or appliances. Safety considerations include ensuring no obstructions in the combustion air supply and avoiding backdrafting conditions. Proper installation prevents carbon monoxide hazards and maintains optimal furnace performance. Always follow safety guidelines and verify compliance with environmental regulations to ensure a safe working environment and reliable system operation.

Ensuring Proper Venting for Efficiency and Safety

Proper venting is essential for the Goodman GM9S96 furnace to operate efficiently and safely. Ensure all venting materials meet local codes and manufacturer specifications, such as approved PVC or ABS pipes. The venting system must be airtight to prevent gas leaks and ensure proper combustion. Install vents with adequate slope and clearance to avoid condensation buildup. Proper venting prevents carbon monoxide hazards and maintains system performance. Regularly inspect venting for damage or blockages. Improper venting can lead to reduced efficiency, safety risks, and potential system damage. Always follow installation guidelines to ensure a safe and efficient heating system.

Electrical and Thermostat Connections

Connect the Goodman GM9S96 furnace to a dedicated 120V or 240V circuit, ensuring compatibility with the thermostat. Follow wiring diagrams for proper connections and safety.

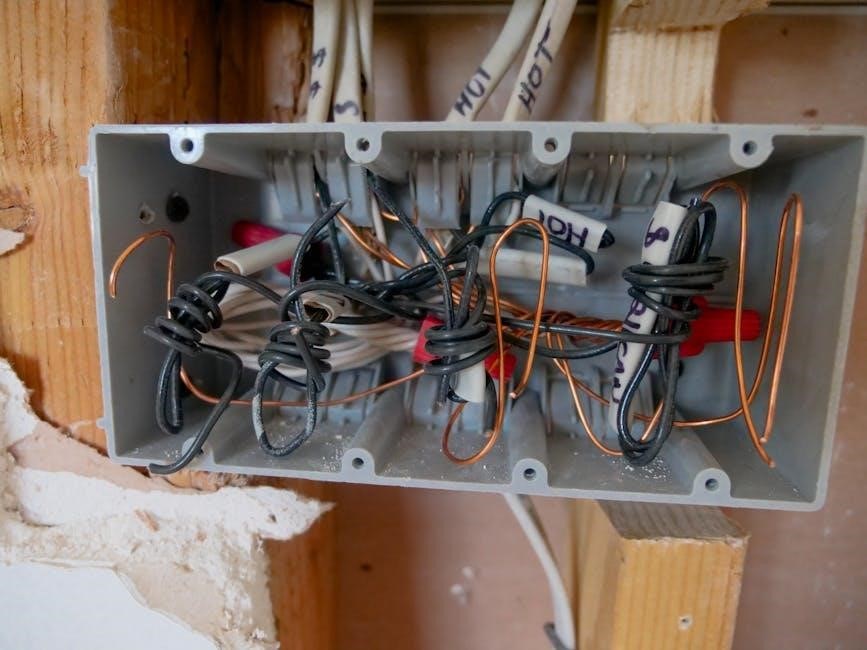

Electrical Wiring and Circuit Requirements

The Goodman GM9S96 furnace requires a dedicated 120V or 240V electrical circuit, depending on the model configuration. Ensure the wiring is appropriately sized to handle the furnace’s power demands, typically requiring 12 AWG or larger wires. The circuit must include a properly rated fuse or circuit breaker to protect against overloads. Grounding the furnace is essential for safety and must comply with local electrical codes. Use heat-resistant and moisture-resistant wiring to prevent degradation. Always disconnect power before performing any electrical work. Refer to the wiring diagram in the manual for specific connections and verify compliance with local and national electrical standards.

Thermostat Installation and Configuration

Install the thermostat in a location free from drafts and heat sources, ensuring accurate temperature sensing. Use a programmable or smart thermostat compatible with the GM9S96 furnace. Follow the wiring diagram in the manual to connect the thermostat to the furnace’s control board. Set the thermostat to the correct heating mode and configure the schedule according to user preferences. Test the system to ensure proper operation. For advanced setups, enable features like geofencing or smart learning. Refer to the manual for specific configuration steps and compatibility recommendations. Ensure all connections are secure to avoid malfunctions and optimize system performance.

Integration with Smart Home Systems

The Goodman GM9S96 furnace can integrate with smart home systems, enhancing convenience and energy efficiency. Ensure the furnace is paired with a compatible smart thermostat, such as those from Google Nest or Ecobee. Connect the system to your home’s Wi-Fi network to enable remote monitoring and control via smartphone apps. Smart home integration allows for voice commands through platforms like Amazon Alexa or Google Assistant. Program energy-saving routines and receive real-time performance updates. This feature enhances comfort and optimizes energy usage. Always follow the manufacturer’s guidelines for compatibility and setup to ensure seamless integration and functionality.

Testing and Commissioning

After installation, conduct thorough testing to ensure the furnace operates safely and efficiently. Verify all components function correctly and meet specified performance standards.

Post-Installation Testing Procedures

After installation, perform a series of tests to ensure the furnace operates safely and efficiently. Begin by checking for gas leaks using a soap solution or electronic detector. Verify electrical connections are secure and meet voltage requirements. Test the ignition system, burner operation, and blower motor to ensure proper function. Check combustion air intake and venting for blockages or leaks. Measure airflow and temperature rise to confirm they align with manufacturer specifications. Finally, test the furnace under various operating conditions to ensure smooth and consistent performance. Address any issues before finalizing the installation.

Commissioning the Furnace for Safe Operation

Commissioning ensures the furnace operates safely and efficiently. Start by verifying all components are correctly installed and connected. Check the gas valve, ignition system, and burner operation. Ensure proper gas flow and pressure, and confirm electrical connections meet specifications. Test the furnace’s operation under various load conditions. Verify the venting system is functioning correctly and free from leaks. Monitor for proper combustion and airflow. Ensure all safety features, such as high-temperature limits and pressure switches, are operational. After successful commissioning, confirm the system meets all safety standards and is ready for daily operation.

Final Checks and Quality Assurance

After installation, perform a thorough inspection to ensure all components are correctly installed and functioning. Verify that all connections, including gas, electrical, and venting, are secure and leak-free. Test the furnace’s operation at full capacity to confirm proper heating and airflow. Check the thermostat for accurate temperature control and ensure safety features, such as emergency shut-offs, are operational. Document all test results and ensure compliance with local codes and manufacturer guidelines. Address any issues immediately to guarantee system reliability and safety, ensuring the furnace operates at peak efficiency and meets quality standards.

Troubleshooting and Maintenance

Identify common issues like ignition failures or uneven heating. Perform routine checks on filters, vents, and controls. Schedule regular servicing to prevent breakdowns and ensure efficiency.

Common Installation Issues and Solutions

Common issues include improper venting, gas leaks, and electrical misconnections. Solutions involve checking vent integrity, tightening connections, and verifying wiring diagrams. Igniter problems may require replacement. Drainage issues can be resolved by ensuring proper slope and flow. Always refer to the manual for specific troubleshooting steps. Addressing these issues promptly ensures safe and efficient furnace operation. Proper installation practices are critical to avoid recurring problems and maintain warranty validity. Regular inspections can help identify and resolve issues before they escalate, ensuring long-term system reliability.

Regular Maintenance Tips for Optimal Performance

To ensure the Goodman GM9S96 furnace operates efficiently, regular maintenance is essential. Replace air filters monthly to improve airflow and reduce energy consumption. Clean the burner and heat exchanger annually to prevent dirt buildup. Inspect gas lines for leaks and tighten connections if necessary. Ensure proper venting and drainage to avoid blockages. Check electrical connections for wear or damage. Schedule annual professional tune-ups to address potential issues early. Monitor furnace performance and address unusual noises or smells promptly; Regular maintenance extends the furnace’s lifespan and ensures safe, reliable operation while maintaining warranty compliance.

Warranty and Service Information

The Goodman GM9S96 furnace is backed by a comprehensive warranty program, ensuring protection for registered units. The warranty typically includes a 10-year limited warranty on major components and 5 years on parts. Proper installation by a certified technician is required to validate the warranty. For service inquiries, contact Goodman’s customer support or visit their official website for authorized service providers. Routine maintenance by qualified professionals is recommended to maintain warranty coverage. Additionally, users can access online resources and manuals for troubleshooting and repair guidance. Always ensure repairs are performed by authorized personnel to avoid voiding the warranty.